Electrical, Automation and Instrumentation Solutions

TOYAM SOLUTIONS offers custom control panels and automation solutions tailored to your specific requirements. Our control panels are designed for ease of use.

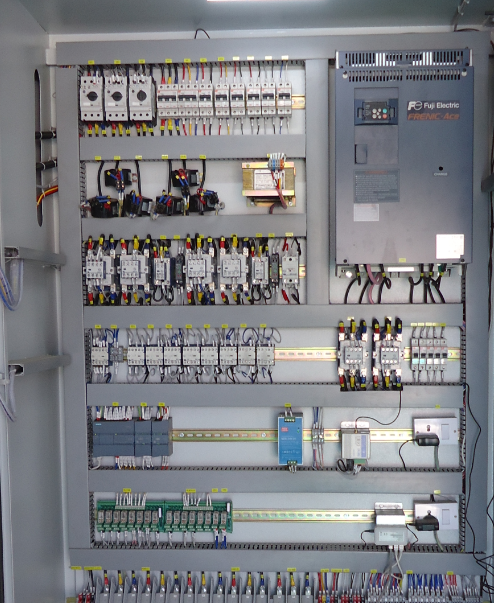

PLC PANELS

Programmable Logic Controllers (PLCs) are rugged digital industrial computers with modular components and can be programmed to control processes. PLCs have wide ranging application from factories, industries to water and waste water infra projects.

They can be programmed to control and monitor any process. OSS team have a rich experience in design and manufacturing of PLC panels for various applications ranging from systems with few IOs to thousands of IOs.

For Applications ranging from Chemical, process industries, Pharma to water and waste water infra projects (WTPs, drinking water pumping stations, STPs, SPS, pumping stations, Lift irrigation pumping stations, etc.). PLC panels we manufacture based on various applications:

PLC panels with Micro PLCs (usually used to monitor and control small non critical process)

PLC Panel with

PLC panel Modular PLC (Usually used to monitor and control larger process)

Panel with hot standby PLC system. (Usually used to monitor and control large and critical processes like: irrigation/ Lift pumping stations, etc.)

Panel with Redundant PLC and Redundant IOs (Used for Highly critical process, such as furnace, oil and gas, power generation)

Remote terminal Units (RTU)

Definition: Remote Terminal Unit (RTU) in is a microprocessor-based electronic device present at geographically distributed remote locations in order to facilitate communication of various devices within the distributed SCADA system. It consists of input-output hardware and communication interface for remote sensing and controlling of ongoing processes.

The sole purpose of an RTU present at the remote site of the SCADA system is to send all the collected data and information to the central station with the help of sensors, monitors, production processes, etc. so that it can be stored and monitored. The data from the remote locations can be sent via various methods such as: VSAT, UHF/VHF Radio, Fibre optic cable, GPRS modems etc. However due to Low installation and recurring cost and increasing reliability of 4G networks GPRS communication is most widely used media of data transfer these days.

OSS have expertise in establishing wireless communication over all media of communications, especially over GPRS communication with or without local static IP

VFD Panels

VFD Control Panel are designed to control the speed of the electric motors. VFD is a power conversion device which converts the fixed voltage, fixed frequency of the input power to the variable voltage, the variable frequency output to control AC induction motors.

With heavy reduction in prices, increasing reliability all and energy saving capabilities, Conventional starter are being replaced by VFDs. VFDs have various other advantages like: Limited starting current, smooth operation, high power factor, easy installation etc.

We provide panels with complete accessories and devices such as Mains switch, MCCB, Input-Output chokes, panel mounted displays etc. for various applications: water supply, air compressors, boilers, paper machinery, food machinery, conveyers and so on.

PCC / MCC PANELS

A MCC center is an assembly of one or more enclosed sections having a common power Bus and principally containing motor control units. Motor control centers are in modern practice a factory assembly of several motor starter. A motor control center can include variable frequency drives, programmable controllers, metering and electrical service at the entrance of the building. A motor control center consists of one or more vertical metal cabinet sections with power Bus provision for plug in mounting of individual controller.

Electrical PCC panels are modular structured electrical control panels used to control power supply in large industrial as well as commercial units. The power supplied to heavy machineries, equipment, motors and transformers are controlled as per the requirement. of electrical loads using these PCC panels. PCC panels cater the needs of various industries like chemicals, plastic, paper, power, oil and natural gas, medicine, Dairies etc. The main quality of panel is to protect and control power distribution for large manufacturing unit.

We manufacture customised Power Control Centre(PCC)/Motor Control Centre Panel to suite customer’s application.

APFC Panels

Due To Variable Load Conditions And Cumbersome Manual Switching Of Capacitors The Power Factor Can Not Be Maintained At Desired Levels. As Close Monitoring Of Power Factor Is Required All The Time To Avoid Penalties And To Minimize The KVA Demand, Automatic Power Factor Correction Panels Are The Best Solutions.

APFC provides compensation for reactive power based on the variations in load conditions to maintain the target power factor. In APFC switching the capacitor is significant as it helps to retain the power factor, the switching is controlled by a Power Factor Controller device that uses the CT feedback to determine the kvar required at any instant. The Power Factor Controller also provides information on the network characteristics such as Active, reactive power, Voltage, power factor for the user to understand. The system generally comprises of Power Capacitors, Controller, firing circuits.The switching system for this depends on the type of compensation.

We manufacture best quality APFC Panels. APFC Panels means Automatic Power Factor Correction Panels. Owing to their energy efficient design, longer serving life, high performance and low maintenance, these APFC panels offered by us are highly demanded in the market. These offered APFC Panels can be customized in accordance with the requirements and demands provided by the customers.